Workplace Safety and Health (WSH) has long been a shared priority across the built environment sector. Yet safety remains a concern especially since the construction sector is entering a period of high volume expansion with more projects, contractors and workers.

In such an environment, uneven standards, cost and timeline pressures, seasonal spikes in incidents, culture gaps and slower technology adoption can quickly erode past gains. As highlighted at this year’s REDAS-WSHC Safety Leadership Forum, these pressures reinforce the need for deeper conversations on how safety practices are applied on the ground.

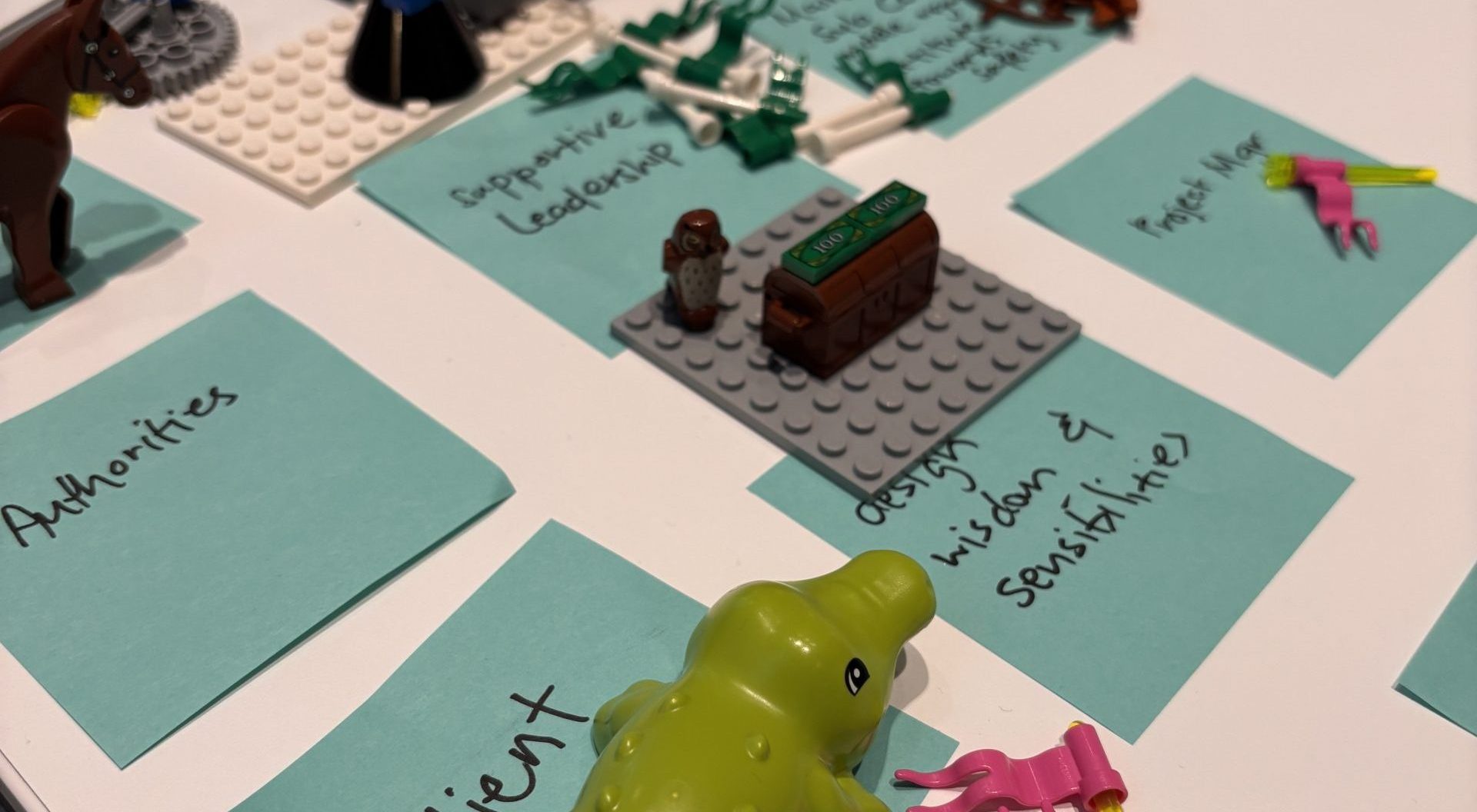

Recognising this, REDAS and SCAL initiated the LEGO® SERIOUS PLAY® (LSP) pilot to create a different kind of conversation that guidelines alone cannot unlock. This pilot created a neutral and structured environment for WSH specialists to reflect together on how planning, sequencing and leadership actually play out during construction.

On 24 November 2025, REDAS and SCAL convened the four-hour LSP pilot workshop at Singapore Land Tower, with 16 WSH Officers (WSHOs) from Boustead Projects, Expand Construction, Hi-Tek Construction, Kwan Yong Construction, Lian Beng Construction, Obayashi Singapore, Or Kim Peow Constructors, Penta-Ocean Construction, Progressive Builders, Samwoh, Santarli Construction, Sato Kogyo, Shimizu Corporation, Teambuild, Wee Hur Construction and Zheng Keng.

Guided by Ms Teo Hwee Ping and Ms Wu Junli, two certified LSP-trained facilitators, participants used LEGO® models to express the daily pressures, behaviours and realities behind safety on site.

The LEGO models enabled participants to uncover shared interests, blind spots and unspoken assumptions that often sit beneath surface-level discussions. This resulted in a honest understanding of where friction tends to occur and what is considered as non negotiable.

1. Leadership & Resources Are the Strongest Foundations

WSH Officers (WSHOs) were unanimous. Safety holds only when top management, PMs and supervisors show clear support and provide proper budgets. Dedicated safety resources, empowered decision-making, and leaders who “walk the talk” set the tone for consistent safe practices.

“When the boss believes in safety, the whole site follows. When he doesn’t, everything becomes a struggle.” – a participant commented

2. Time, Cost & Client Pressures Drive Real-World Trade-Offs

Many safety lapses do not stem from unclear rules, but from compressed timelines, manpower shortages and cost constraints. When pressures rise, workers and supervisors face difficult choices, and safety can become negotiable. WSHOs highlighted that asking teams to “go faster” often creates preventable risks.

3. Design for Safety Is an Under-Used Lever

Participants emphasised that many hazards can be eliminated at the design stage, long before construction begins. Good design, better sequencing and early coordination reduce risk more effectively than downstream controls or extra paperwork.

“By the time a risky design reaches the site, it’s already too late. Design wisdom matters.We can see the hazard the moment we look at the drawing.” – a participant said

4. Human Behaviour: The Biggest Risk & the Biggest Enabler

Models of the “nightmare worker” revealed recurring behavioural challenges:

- shortcuts and improvisation

- complacency from “experienced” workers

- new workers unaware of risk

- unsafe habits spreading through peer influence

At the same time, engaged supervisors and motivated teams were identified as some of the strongest positive drivers of safety culture.

5. What Helps vs What Hinders

When participants marked their models with green (enablers) and pink (constraints), clear clusters appeared:

- Green flags: supportive bosses, PMs who prioritise safety, proper budgets, competent teams.

- Pink flags: tight budgets, resource strain, schedule pressure, misaligned mindsets, and inconsistent supervision.

6. Closing Messages

The session ended with each WSHO choosing one LEGO® brick to encourage peers; binoculars for foresight, bridges for connection, cogwheels for system alignment, and skeletons to remind everyone that every worker must go home whole.

Despite facing heavy responsibilities, participants left with renewed solidarity, clarity and pride in their role as the “unseen structure” that keeps the built environment safe.

A big thank you to our venue sponsor, Singapore Land, our partner, SCAL, our facilitators and our participants for their open collaboration on this pilot exercise.